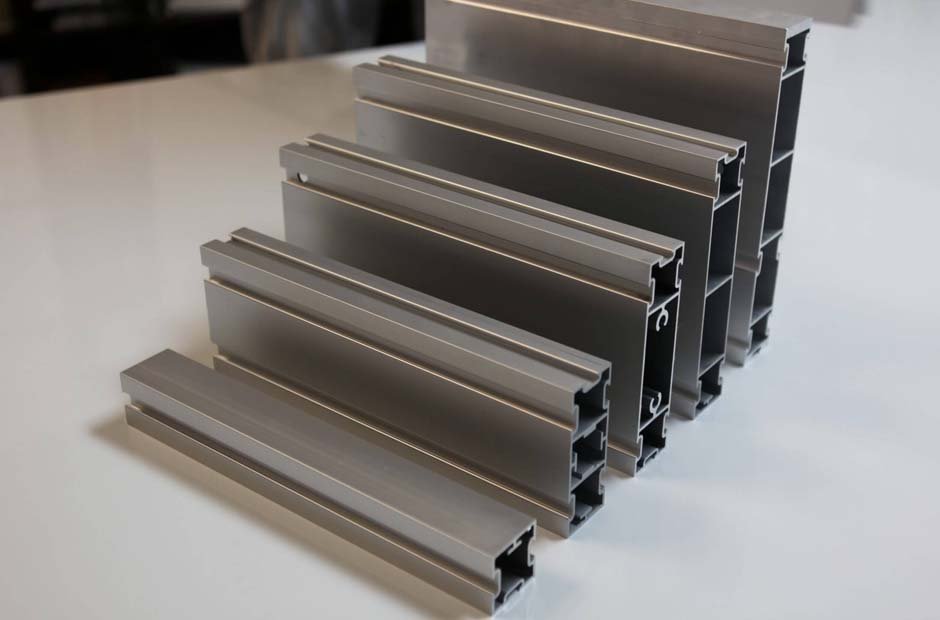

Aluminum extrusion is the manufacturing process that brings forth the different cross-sectional types of aluminum alloy profiles. You drive the alloy mix through a steep opening that acts as the die shaped in the preferred cross-section profile. What aluminum extrusion gives you is the freedom to create extrusions in any size or shape you desire.

On top of that, aluminum extrusion also offers several other advantages, including high corrosion resistance, low costs, and offering high strength-to-weight ratio. There are a few cons of aluminum extrusion, however, and one of the main ones is the minimum wall thickness for extrusion.

Several factors influence this thickness, the primary ones being the type of ally used, the speed of the extrusion process, the design, and the temperature. Also, the stronger and harder the alloy, the thicker the minimum wall thickness for aluminum extrusion.

The lowest wall thickness for aluminum extrusion is determined by the form and smallest circumscribed circle, as well as the alloy. Wall thickness tolerance will be roughly +/- 10% of the wall thickness.

To be more specific, according to Profile Precision Extrusions, the minimum wall thickness for extruding alloy 6063 is 0.635 mm. However, according to the Aluminum Guide, the minimum viable thickness of the profile of alloys, like 6063 and 6060, should meet the following conditions: It should not be less than 1.2 mm and should have at least 1% alloy profile cross-section size.

So, the exact minimum size depends on various aspects. There’s no one size fits all. For instance, hollow profiles have a higher minimum wall thickness than, say, solid profiles.

How is the minimum wall thickness measured?

One way to measure the minimum wall thickness for extrusion is by subtracting the alloy profile’s inner diameter from its outer diameter and then dividing the difference by two. For example, if the inner diameter is 10mm, and the outer one 12mm, then the minimum wall thickness is (12mm -10mm)/2.

You can also measure the gap using a micrometer or a caliper to get the distance between the outer surface and inner surfaces. For irregular shapes, the above methods may not work. In such cases, you can use computer-aided design software to get the measurements.

Bottom line

Generally, having a uniform alloy with a minimum aluminum thickness with the right structural features is very important. It not only costs less, but it is easier to extrude than a complex aluminum profile.

Additionally, uneven wall thickness can lead to various issues when extruding and cooling by aluminum extrusion equipment, which can cause the end product not to have your desired shape and size.

So, avoid neighboring wall thicknesses with a ratio greater than 2 -1 and go for rounded corners to easily transition from walls with various thicknesses. This will go a long way to aid with the flow of aluminum.

Also, keep in mind that higher pressure, temperature, and speed allow thinner walls to be extruded easily. Nonetheless, these features also have disadvantages like minimized surface quality, enhanced risk of defects, and enhanced die wear. As such, it is crucial that you find a balance between these factors if you want to get the best quality and seamless aluminum extrusion.