In the realm of industrial engineering, the bellows actuator stands as a pivotal component, revered for its versatility and crucial role in various applications across multiple industries. Characterized by its accordion-like structure, the bellows actuator serves as a force-transmitting device capable of converting fluid, pneumatic, or mechanical energy into mechanical motion.

What is a Bellows Actuator?

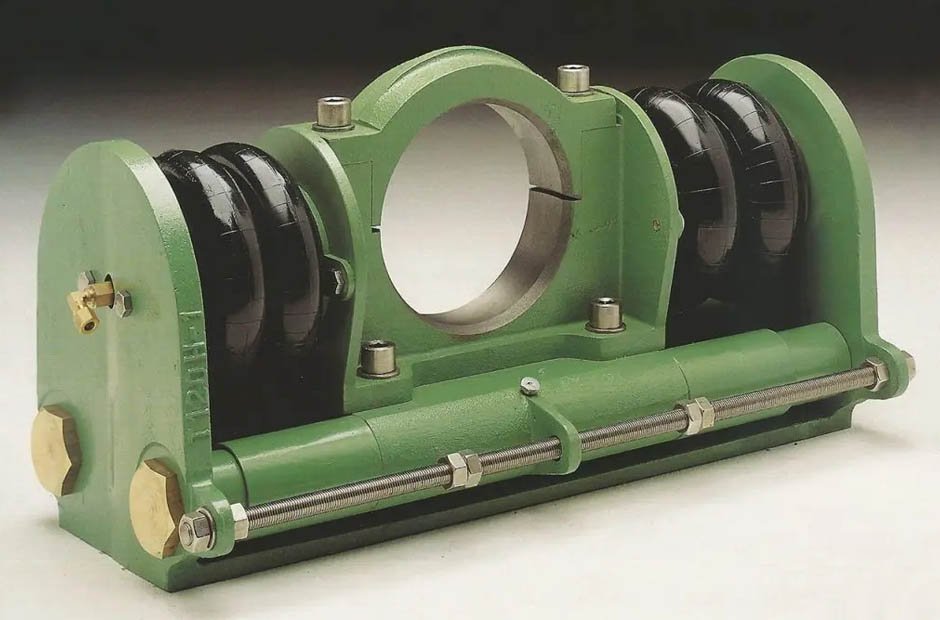

A bellows actuator is a mechanical device primarily designed for linear or axial motion generation through the expansion and contraction of a bellows—a flexible, accordion-like component. This actuator leverages the principle of converting pressure or energy into movement. The bellows structure, typically made of metal or elastomers, is capable of elongating and contracting while maintaining its shape.

How Does it Work?

The functionality of a bellows actuator relies on the manipulation of pressure differentials within its structure. When subjected to external forces such as pneumatic, hydraulic, or mechanical pressure, the bellows expand or contract accordingly.

- Expansion: Application of pressure causes the bellows to elongate, creating a linear motion.

- Contraction: Release or reduction of pressure allows the bellows to revert to its original shape, causing it to contract and generate the reverse motion.

Anatomy of Bellows Actuators

The fundamental design of a bellows actuator comprises a series of pleated, flexible elements made from materials like elastomers, rubber, or metal alloys. These materials offer resilience to pressure, enabling the actuator to expand and contract smoothly. Typically, when pressure is applied, the bellows extend, and upon release or reduction of pressure, they retract. This basic principle of expansion and contraction facilitates movement in various applications.

Functionality and Mechanism

Bellows actuators operate on the principle of displacement. When subjected to external forces like air pressure or hydraulic fluid, these actuators undergo expansion or contraction, subsequently generating linear or rotary motion. The controlled movement produced by bellows actuators finds application in valves, control systems, pumps, and numerous other mechanisms demanding precise and controlled motion.

Applications in Diverse Industries

The adaptability of bellows actuators spans across a wide array of industries:

Aerospace Industry

In aviation, bellows actuators play a vital role in controlling mechanisms, such as flap systems and wing surfaces. Their reliability and precision contribute significantly to flight safety and performance.

Manufacturing and Automation

Within manufacturing, bellows actuators are integral components in automated machinery, contributing to the precise movement and positioning of robotic arms, conveyor systems, and assembly lines.

Medical Equipment

The healthcare sector harnesses bellows actuators in medical devices like surgical tools and diagnostic instruments, leveraging their accuracy and reliability.

Automotive Sector

In automobiles, these actuators contribute to various applications, including engine controls, exhaust systems, and suspension components, ensuring optimal performance and efficiency.

Robotics and Electronics

Bellows actuators find applications in robotics and electronics, assisting in the precise movement and functioning of small-scale mechanisms in consumer electronics, industrial robots, and more.

The Role of 1T15M4 Firestone Industrial Bellows Actuator

Among the plethora of bellows actuators available, the 1T15M4 Firestone Industrial Bellows Actuator stands out due to its reliability, durability, and precision. Its engineering excellence makes it a preferred choice in critical applications where accuracy and performance are paramount.

Conclusion

The significance of bellows actuators in modern industries cannot be overstated. Their versatility, reliability, and precision in converting various forms of energy into mechanical motion render them indispensable across multiple sectors. As technology advances, these actuators continue to evolve, further expanding their applications and enhancing the efficiency of numerous industrial processes.