Most HDD problems do not start at the reamer. They start when the pilot drifts, the signal gets weird, and the crew keeps pushing because the schedule is tight.

A locating system exists for that moment. Not for marketing. For decision making when the ground refuses to cooperate and the utility corridor does not forgive mistakes.

This guide explains what this tool is, where it earns its keep, where it does not, and how to buy or sell locating gear through UCG HDD without surprises.

Quick Answer

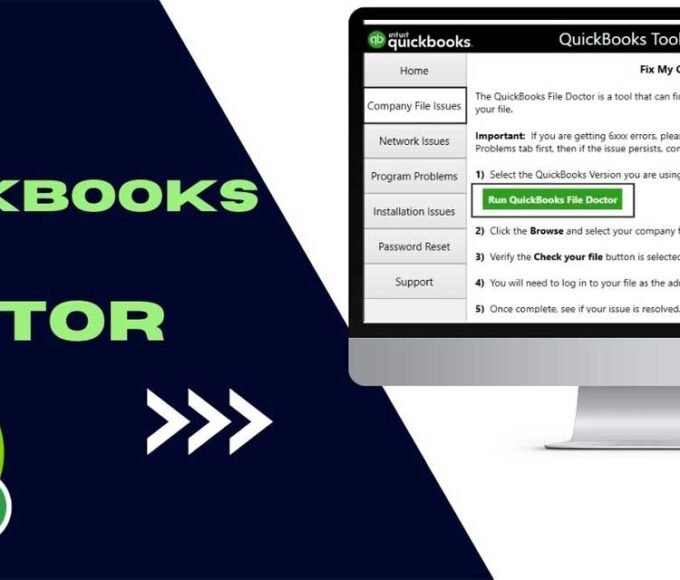

A DigiTrak F5 is a walkover locating system used during HDD to track the position and orientation of the drill head through a transmitter in the housing and a handheld receiver. It helps crews steer the pilot bore with fewer guesses and fewer expensive decisions that show up later as daylighting, re drills, or change orders.

You really need a higher confidence locator when the jobsite punishes small errors. That usually means dense utilities, tight corridors, long crossings, or persistent electrical noise. Those conditions create the kind of bad data that slows the bore, drives more potholing, and increases strike risk.

You can often run simpler gear when you have open space, clean signal, short bores, and a wide margin for error. The catch is that those conditions are not guaranteed, even on a job that looks simple on paper.

Use these quick field rules:

- Prioritize a stronger locating setup when you have tight utility corridors, road or rail crossings, long bores, or frequent interference.

- Consider a simpler setup when you are in low interference areas, have short and shallow bores, and have room to verify with potholes.

- If your crew keeps losing time to signal questions, you are paying for uncertainty already, just in labor and downtime instead of equipment.

A practical decision is to buy for the hardest recurring job you run each month. If the hardest job keeps showing up, your locator should not be the weak link.

What Is The DigiTrak F5?

Think of it as your steering dashboard for walkover HDD. The receiver gives the locator operator real time information about where the drill head is and how it is pointed. That lets the driller correct early, when a small adjustment still matters.

A complete system is not just a handheld device. A typical package includes a handheld receiver, a transmitter, a remote display for the drill, a battery charger, and rechargeable battery packs. That system framing matters because crews get burned when they buy one piece and assume the rest will appear later.

The point is not to own a locator. The point is to reduce uncertainty at the exact moment uncertainty gets expensive. On a clean job, you confirm what you already believe. On a hard job, you catch drift before it becomes a miss.

Below is the plain English view of how it works and what you should confirm before you buy.

How A Walkover Locating System Works

Walkover locating uses a transmitter in the drill head housing and a receiver above ground. The locator operator tracks the signal as the head advances, then communicates depth and steering direction back to the driller. That back and forth is where good crews separate themselves.

In practice, the receiver data becomes a steering workflow. You confirm the front locate. You verify depth. You check roll and pitch. You call corrections while the head still responds cleanly. You keep the bore inside the corridor before the corridor becomes a trench.

The key operational detail is discipline. A locator does not replace potholing, job planning, or clear communication. It supports them. When the crew treats readings as a decision tool and verifies when something looks off, the job stays under control.

Here is a simple stress test for your process. When the data looks wrong, does your team slow down and verify, or do you push through and hope it cleans up on the next rod. Crews that verify early finish faster over the full week, even if they move slower in the bad zone.

What You Typically Get In An F5 Setup

Most buying mistakes come from unclear expectations about what is included. A complete setup should cover the receiver side, the transmitter side, power, and the ability to see data at the rig. That last part matters because a remote display reduces miscommunication and speeds up corrections.

You also need to think in terms of transmitter options. Many crews run into interference often enough that flexibility becomes a real advantage. Frequency choices, configuration options, and the right style of transmitter for your normal work can make the difference between steady progress and constant second guessing.

Before you buy, confirm three practical things:

- The exact items included in the package and whether it is ready to work on day one.

- The transmitter type and configuration that match your job mix and your typical interference level.

- The power and charging pieces that keep the system running through a full shift.

If you do that upfront, you avoid the most common problem in used locating purchases. You avoid owning a pile of parts that still cannot drill a bore.

Why Crews Choose This Class Of Locator

Contractors do not buy locating equipment because it is fun. They buy it because the cost of being wrong is high. A solid walkover system pays for itself in avoided downtime, fewer re drills, and fewer stop work moments when something does not make sense.

This locator class fits how most U.S. HDD crews actually operate. You can scale it from smaller fiber drops to larger utility installs without changing your entire process. When you step into urban corridors, the value shows up in confidence and speed.

If you run mixed jobs, you want gear that does not force you to gamble. A practical locator lets you verify fast, correct early, and keep the bore on plan.

That is the real reason crews stick with the same class of system once they have trained good operators.

Where The Locator Fits In The HDD Workflow

Locating is not a single event. It is a sequence of decisions across the bore. Receiver data matters most when the drill can still respond to steering. That is why the pilot bore is the main stage, even if the most dramatic failures show up later.

Your workflow should match the phase of the job. During pilot, you steer. During reaming and pullback, you manage risk zones. During documentation, you protect yourself and your customer.

The sections below show where data usually earns its keep and how to think about enough locating for each phase.

Pilot Bore Is Where Locating Makes The Money

If you want one phase where locating pays for itself, it is the pilot. The pilot bore sets the geometry of the job. Every later step follows that path, including where the reamer loads up and where the product pullback fights you.

In the field, pilot locating is about keeping small errors small. If the head trends up and you do not catch it early, you lose depth margin near a crossing. If the head trends sideways and you ignore it, you drift toward utilities you promised to avoid.

A strong pilot workflow has a rhythm. Front locate, confirm depth, call correction, verify again. The best crews do this without drama. They treat the bore like an instrument approach, not a road trip.

If you hear a crew say we will correct later, you are listening to a future delay. The pilot is where you prevent that. It is also where better locating reduces stress on the driller, because the calls arrive as clean decisions instead of arguments.

Reaming And Pullback Still Need Targeted Verification

Some crews stop thinking about locating after the pilot. That can work on easy jobs. It can also create surprises when conditions change.

Reaming and pullback are about risk management. You are not steering the same way, but you still need confidence in critical zones. That includes entry and exit, known utility clusters, and any section where you do not have room for a mistake.

The value is not constant across the full length of the job. It spikes at constraints. If you plan those spikes, you move faster overall. You avoid panic checks and last minute potholing when the schedule is already breaking.

A practical approach is to pre identify verification stations before you start. Mark where you want extra confirmation. Use consistent calls and consistent checks. Keep the crew aligned on what good looks like before it becomes a disagreement.

Documentation And As Built Expectations

Even when the drilling goes well, paperwork can still hurt you. Documentation is a form of risk control. It helps you prove what you did, when you did it, and why it was reasonable.

In many utility environments, the customer expects more than we stayed on line. They want evidence of control. That can be as simple as recorded checks at key points or notes tied to stationing and potholes.

Good documentation also protects the crew when the jobsite becomes political. If a locate mark turns out to be wrong or a record is outdated, your notes can show that you verified, slowed down, and acted responsibly.

Keep documentation practical. Focus on decisions and checkpoints, not bureaucracy. Document more when the job has tighter tolerances, more stakeholders, and higher consequences.

When You Really Need A Stronger Locating Setup

Some jobs punish uncertainty. Others tolerate it. Your goal is not to own the most expensive equipment. Your goal is to match locating confidence to the job’s consequence curve.

The following scenarios consistently justify investing in a reliable locator system. They are also the jobs that drive repeat work and better margins because customers pay for teams that control risk.

Urban Work With Dense Utilities

Urban HDD is not hard because the drilling is different. It is hard because the map is crowded and the tolerance is thin.

In a dense corridor, you have more crossings, more parallel utilities, and less room to move. That means a small depth error can become a real conflict. A small lateral drift can put you on the wrong side of the pothole you trusted.

In those conditions, your crew needs clear reads and a calm workflow. You need to verify fast and correct early. If the data looks distorted, you need the discipline to stop and figure out why. That discipline is what keeps production steady.

A stronger locating setup also changes how you bid. It lets you price risk with less fear. You can commit to tighter corridors because you have a method to manage them. That is not hype. It is how experienced contractors grow into higher value work.

If most of your backlog involves urban fiber, gas, water, or power related corridors, this is the scenario that usually makes the purchase easy to justify.

Crossings And Constrained Corridors

Crossings create a different kind of pressure. The customer often cares more about the crossing than the rest of the bore. The inspector often watches the crossing. The penalty for a miss often sits at the crossing.

Road, rail, and pipeline crossings also reduce your available correction space. If you are too shallow, you cannot simply dip down at the last second. If you are too deep, you may violate the design intent or create pullback issues.

A good locator helps you hold depth and direction with fewer surprises. It also helps you communicate with stakeholders. When you can show that you verified at planned points, you look like a professional crew, not a lucky one.

Treat crossings like a mini project inside the project. Plan verification points. Daylight where required. Keep a clean log of calls and checks. Your equipment supports that discipline, but the discipline is the real tool.

High EMI And Interference Zones

Interference is where crews lose time. It is also where crews start making bad decisions because they want the job to move.

Sources of EMI are common near overhead power, substations, industrial corridors, and congested utility bundles. The symptoms look like unstable depth readings, inconsistent front locates, and a general feeling that the system is lying.

The correct response is not to argue with the receiver. It is to treat the environment as part of the job. Verify more often. Use controlled checks. If needed, adjust your plan rather than forcing the bore through a bad zone.

The real cost of EMI is not just slower drilling. It is the temptation to trust bad data. If your crew has ever pushed through weird readings and regretted it, you already know why interference scenarios justify better equipment and tighter procedures.

When A Simpler Locator May Be Enough

Not every bore needs the same level of locating horsepower. Some jobs are clean and forgiving. Buying for those jobs alone can lead you to undershoot what you will need later.

This section exists for one reason. It helps you make a decision you will not regret when the job mix changes.

Low Interference Open Work And Short Bores

If you drill in open areas with low interference, fewer crossings, and wide corridors, you can often run simpler locating gear. The key is that you still need a disciplined workflow. Even easy jobs can hide surprises.

Short bores with shallow depth targets are also more forgiving. You can pothole more easily. You can adjust more easily. If something looks off, you have room to stop and verify without destroying the schedule.

The trap is assuming that simple job equals simple conditions. Soil changes, moisture changes, and nearby utilities can still distort a signal. If your crew operates with a relaxed mindset on easy jobs, that habit carries into harder jobs.

A balanced approach is to buy for the hardest slice of your work, not the easiest. When you step into tighter corridors, your locator becomes either a capacity upgrade or a limiting factor.

If You Use Wireline Or Gyro Guidance

Wireline and gyro systems live in a different category. Crews use them for specific technical needs, not as a general replacement for walkover locating. If your projects regularly require those methods, you already have a more engineered workflow.

For many contractors, the real decision is not wireline versus walkover. It is walkover for most jobs, then a different method when constraints demand it. That is where this locator class often fits. It covers the majority of work without forcing you into a complex setup every time you pull onto a site.

If you do have wireline capability, walkover locating can still play a role in planning and verification. It can also support crews when a job shifts from expected conditions to messy ones.

Keep the decision grounded. Choose the method that matches the constraint. Do not buy a specialized method to solve a general problem, and do not expect a general method to solve a specialized one.

Real World Limits And What Causes Bad Readings

Locators are not magic. They are instruments. Instruments behave differently in different environments. If you buy with realistic expectations, you get more uptime and fewer surprises.

This section covers two failure modes that waste the most time on site. Signal challenges from soil and interference challenges from the built environment. It also includes a checklist you can run before you blame the equipment.

Signal Challenges And The Digitrak Sonde F5

The transmitter is where the signal begins. If you run the wrong transmitter option for the conditions, you can create your own problems. Flexibility exists because interference is not theoretical. It is what forces crews to change strategy mid bore.

Conductive soils, high moisture, and certain site conditions can reduce signal strength and distort readings. The symptom is not always a total loss. Often it is inconsistent results that make operators second guess themselves.

When that happens, you need a process. Do controlled checks. Confirm your setup. Consider a different transmitter strategy. Increase verification frequency in the bad zone. Slow the job down before the job stops itself.

A good operator also watches for too good to be true data. If the readings suddenly look perfect after a stretch of bad behavior, verify before you trust it. That single habit saves crews from expensive drift and re work.

EMI Calibration And Operator Technique

Interference can make a good system look broken. Calibration and technique can make a good system look unreliable. Those truths can coexist.

Start with setup discipline. If your receiver is not set up correctly, the jobsite will amplify the error. If your batteries are weak, the system may behave in ways that look like interference. If your crew communication is sloppy, even clean readings turn into bad steering.

EMI adds another layer. In high EMI zones, you should expect to spend time verifying and adapting. That is normal. What is not normal is ignoring signal behavior and pushing ahead because the schedule is tight.

The practical fix is consistent. Verify your setup before the bore. Use a repeatable locating cadence. When the readings look off, stop and isolate the cause. Do not average bad data in your head.

A crew that respects the instrument finishes faster over the full week, even if they move slower in the worst stretch.

A Checklist Before You Blame The Locator

When something feels wrong, run this checklist before you assume the system failed:

- Confirm the transmitter and housing match the job and the drill head setup.

- Check battery condition and charging status for the receiver and any remote display.

- Verify you are using the expected transmitter mode for the environment.

- Move away from obvious EMI sources and re check signal behavior.

- Re run a basic setup verification before you resume steering calls.

- Tighten communication. One caller, one set of terms, no guesswork language.

- Increase verification points through the bad stretch.

- If data stays inconsistent, change strategy rather than forcing progress.

This checklist does not replace training. It replaces panic. It also reduces downtime because you stop chasing ghosts and start isolating the cause.

If you follow it, you will know when the problem is environmental, procedural, or equipment related.

Simple Comparison To Other Locating Options

Most buyers do not need a brand war. They need a decision framework that matches how real bores fail.

The core variables are locating confidence in bad conditions, ease of use for your crew, and the cost of downtime when you are wrong. The last variable is the one that gets ignored until a crew sits idle for half a day.

Use this three bucket framework:

- Entry level walkover locating gear can work well in clean conditions. It often becomes the limiting factor in urban work, interference zones, and longer bores where verification speed matters.

- Higher end advanced systems can make sense for specialized conditions, but they can also be more than you need for mixed work. If you buy too far above your job mix, you tie up capital that could have gone into rods, tooling, or another crew.

- Wireline and gyro methods address specific constraints. They are not the default for most bores, and they carry their own process and training cost.

Here is a practical way to choose. List your hardest recurring sites and what makes them hard. If interference and tight corridors show up often, buy for those conditions. If they show up rarely, consider renting or partnering for those jobs.

The reason many contractors land in this middle class is simple. It supports mixed job types without forcing constant compromises. It also gives crews a platform they can standardize around, which reduces training friction and improves call consistency.

Buy DigiTrak F5 Equipment On UCG HDD

If you buy used locating gear, the goal is simple. Get equipment that is inspected, complete, and ready to work without a week of chasing missing parts.

If you want to compare DigiTrak F5 sale options and price ranges in one place, browse the catalog here: https://ucghdd.com/collections/digitrak-f5.

On that page you can see current availability and pick the package that matches your crew’s workflow, whether you need a full setup or a specific component to get a rig back in the ground.

Step By Step Ordering Process

Use this ordering workflow to avoid the usual buying mistakes:

- Start at the collection page and decide whether you need a full locating package or a specific component.

- Open the product listing and read what is included. Confirm receiver, transmitter, power items, and any display components.

- Match transmitter configuration to your work. If you see mixed interference conditions, prioritize flexibility.

- Review warranty terms for transmitters so you know what is covered and how claims work.

- Place the order through checkout and confirm shipping information.

- When the shipment arrives, do a fast receiving check. Verify contents, power up, and basic function before the equipment is scheduled for a bore.

A good habit is to schedule a bench check the same day the box arrives. That keeps problems from showing up on the morning of the crossing.

Why Buying From UCG Reduces Risk

Used equipment is only a deal when it works on your next bore. Buying from a dedicated HDD supplier reduces the common risks that come with random listings, missing components, and unclear condition.

The operational benefit is straightforward. You spend less time troubleshooting and more time drilling. When the crew is down, the cost is not the part. It is the crew, the traffic control, the rescheduling, and the customer conversation.

If you want the best result from a purchase, buy for completeness and policy clarity. That approach can cost more than a bargain listing, but it usually costs less over the full season.

Sell Your HDD Equipment To UCG HDD

Many contractors end up with extra locating gear for simple reasons. A crew upgraded. A project ended. A transmitter became unreliable. The equipment sits because selling it feels like a hassle.

UCG HDD uses a clear three step flow. You describe what you have and share contact information. If there is interest, you ship the equipment for evaluation. You get paid if you accept the offer.

To move faster, prepare your information like a contractor, not like a yard sale.

What To Prepare Before You Reach Out

To get an accurate offer, provide:

- The model and what is included.

- Clear photos, plus video if possible.

- Known issues, including intermittent behavior.

- Any repair history and visible wear that affects value.

Be direct about condition. It saves time. It also reduces the back and forth that delays offers.

If you are selling because you want to upgrade, mention that early. A trade in conversation can reduce friction and shorten decision time.

What Happens Next And Timing Expectations

After you send details, expect a confirmation on whether the equipment is a fit for evaluation. Once the item arrives, the evaluation step determines condition and value.

Timing depends on shipping time and evaluation workload, so treat schedule as variable. The way to reduce variability is simple. Provide complete information upfront, ship promptly, and package securely to avoid damage in transit.

If you accept the offer, payment follows. If you decline, you can request the item back. The process is designed to keep you in control of your equipment while you evaluate an offer.

FAQ

Is This Locator A Good Fit For Urban HDD

If your work includes tight corridors, crossings, and frequent interference, a reliable walkover system is a practical fit. Urban work punishes uncertainty. That is where crews value predictable readings and a workflow they can standardize.

The key is matching the system to how you actually drill. If your crew already runs disciplined locating calls and verification points, better equipment amplifies that discipline. If your crew does not, the first investment should be training and process.

What Causes Depth Readings To Look Wrong

The common causes are interference, soil conditions that weaken the signal, setup errors, and operator technique. When readings look wrong, slow down and isolate the cause.

Use a checklist. Confirm transmitter mode and power. Move away from obvious EMI sources. Re run a basic verification. Then decide whether to change strategy or increase verification points.

What Should I Check Before Buying Used Locating Gear

Focus on completeness and policy clarity. Confirm what is included in the system and whether the package matches how you run jobs. Also confirm warranty expectations for transmitters so you know what is covered and what is not.

If you buy for jobsite conditions instead of buying for a deal, you reduce downtime risk.

Can I Return A Used Locator If I Change My Mind

Return rules vary in used equipment markets. Confirm current terms before you buy so you do not get surprised.

The practical fix is to confirm fit before ordering and to test on arrival.

Do I Need Special Transmitter Options

If you work in varied interference environments, transmitter flexibility matters. Match your transmitter strategy to your job mix.

If you are unsure, start by listing your hardest recurring sites and what makes them hard. That list usually makes the correct choice obvious.