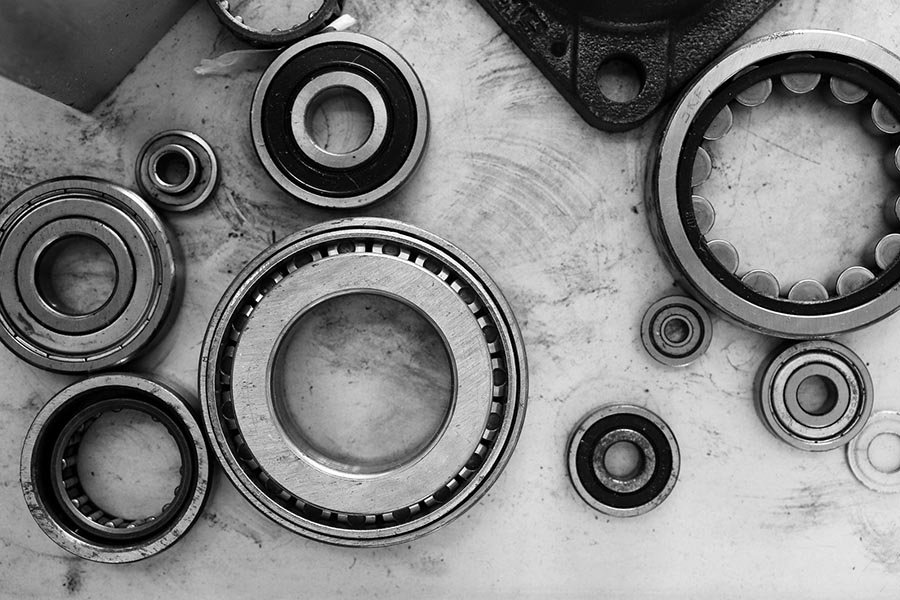

A bearing is a device that reduces friction in rotating axles and shafts. Its primary purpose is to ease the weight exerted on the shaft, helping it turn easily and ensuring the machine performs as required. They also prevent moving parts from grinding against each other, which helps minimise wear and tear.

Bearings have a wide range of applications in various industries, including transport, office equipment and general manufacturing. Their application depends on the specific structural design. So, to understand what they are useful for, it is essential to learn the different types of bearings on this site.

Types of Bearings

There are two primary types of bearings;

- Ball bearings

- Roller bearings

These are subdivided into subcategories based on the design of the bearings and how they suit different applications. Here is a breakdown:

Ball bearings

As the name suggests, ball bearings use balls as their rolling elements. They utilise two bearing rings or raceways to minimise surface contact and friction across moving planes. Ball bearings are the most common in many machines because they rotate quickly. However, they cannot support substantial loads, which makes them less suitable for heavy machinery.

Here are the various types of ball bearings;

- Deep groove ball bearings – Suitable for high-speed rotating machines due to their low torque design.

- Angular contact ball bearings – These are well-suited for machines that bear combined loads (cases where there are high radial and axial forces to bear).

- Self-aligning ball bearings – Suitable for machines with misaligned shafts and housings (an issue that can cause the shaft to deflect when rotating).

- Thrust ball bearings – Designed to absorb axial forces in a single direction, which makes them suitable for handling thrust loads while operating at high speeds.

Roller Bearings

Roller bearings perform the same purpose as ball bearings. However, they use cylindrical rolling elements (rather than balls) to carry weight and minimise friction in rotating shafts and axles. Generally, roller bearings can carry more load than ball bearings – but the design factor makes them relatively slower and less suited for high-speed rotation.

These types of bearings are further subdivided into four subcategories, each with varying designs to suit different applications. Here are the various types of roller bearings:

- Cylindrical roller bearings – These have cylindrical roller elements, which increase the surface area in contact with the raceway and ensure a higher radial load rating.

- Tapered roller bearings – These have conical roller elements arranged between tapered inner and outer raceways. With the special contact angle, these bearings can carry higher axial and radial forces in one direction. However, they can be paired to support loads in multiple directions.

- Needle roller bearings – These use long, thin cylindrical elements (needle rollers). Their small design makes these bearing types suitable for constricted spaces in heavy machinery.

- Spherical roller bearings – Spherical roller bearings have the same working principle as self-aligning ball bearing; however, they use spherical rollers in place of ball rollers. With their higher radial load rating, these bearings are suitable for heavy machines with misalignment between the housing and shaft/axle.

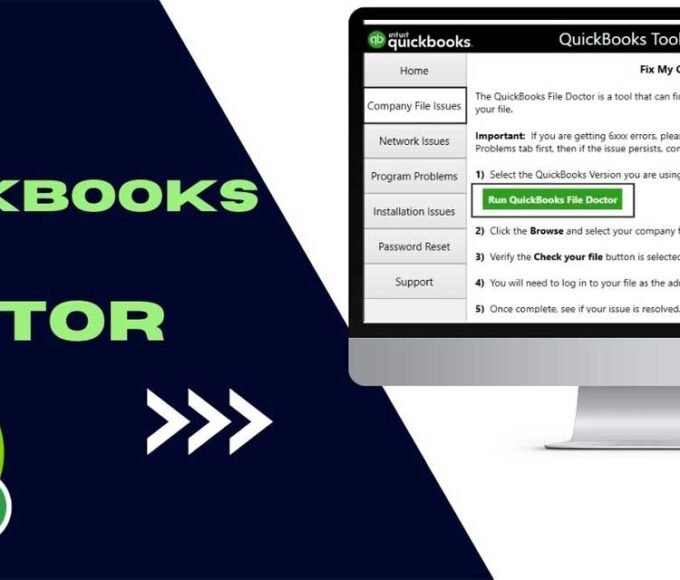

To Sum Things Up

The application of a bearing depends on its structural design. So, as you shop, it is essential to consider the type and size of the machine you intend to install it on. If you have a heavy-duty machine, it is advisable to choose roller bearings. On the other hand, ball bearings might suit you better if you have a smaller machine with a higher operational speed.