In the world of precision machinery, the spindle plays a pivotal role in deciding output accuracy and the equipment’s overall lifespan. Regular wear and tear and specific operational stresses can lead to spindle degradation over time. This article explores the process of spindle rebuilding – an essential maintenance technique that restores spindle functionality, enhances machine accuracy, and extends the equipment’s operational lifespan. The spindle’s health directly impacts the final product’s quality, making its maintenance a top priority for manufacturers. Timely spindle rebuilding saves costs in the long run and ensures consistent quality in manufacturing processes. Understanding and implementing spindle rebuilding, alongside utilizing a spindle testing device, can be seen as an investment in the machinery’s future performance and reliability.

Understanding Spindle Wear and Tear

Spindle wear and tear is an inevitable consequence of machine operation. Factors contributing to this wear include bearing degradation, contamination from external particles, and thermal stresses. Recognizing the symptoms, such as increased vibration, noise, or decreased accuracy, is crucial for timely intervention. Over time, these issues can compound, leading to more significant problems and even machine failure. Regular monitoring of spindle performance can preemptively identify wear and tear, allowing for scheduled maintenance rather than costly emergency repairs. Understanding the root causes of spindle wear is fundamental to developing effective maintenance strategies and schedules.

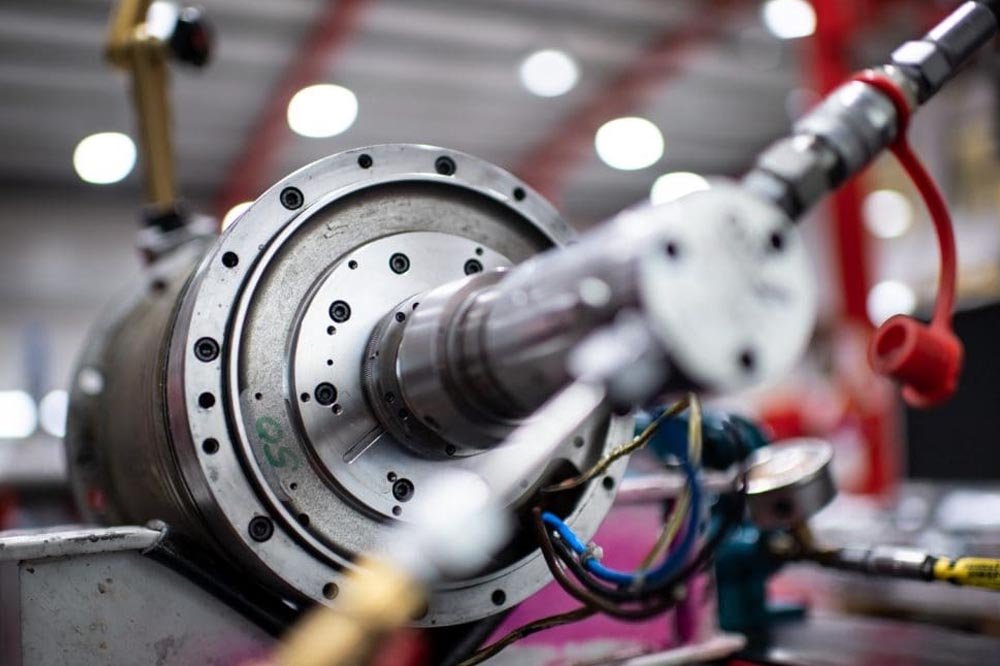

The Spindle Rebuilding Process: A Step-by-Step Guide

Spindle rebuilding is a meticulous process that involves several key steps. The process begins with thoroughly inspecting and disassembling the spindle, then cleaning and assessing each component. Damaged parts are either precisely repaired or replaced. The spindle then undergoes a process of reassembly, lubrication, and rigorous testing. Each process stage requires high technical skill and precision, ensuring the rebuilt spindle meets exacting standards. Specialized equipment is often used in the assessment and repair stages to achieve optimal accuracy. The final testing phase ensures that the spindle operates as efficiently as the original if not more so, reinforcing the value of the rebuilding process.

Advantages of Regular Spindle Maintenance

Regular maintenance, including periodic spindle rebuilding, offers numerous benefits. It ensures consistent machining accuracy, reduces the likelihood of machine downtime, and extends the equipment’s overall lifespan. By identifying and addressing issues early, manufacturers can avoid the exponential costs of major breakdowns. Regular maintenance also facilitates smoother operation, reducing wear on other machine components. Ultimately, this proactive approach contributes to a more sustainable and cost-effective manufacturing operation.

Choosing the Right Spindle Rebuilding Service

The choice of a spindle rebuilding service is critical. It requires a service provider with expertise in precision machinery, a track record of quality service, and the ability to work with a wide range of spindle types. It is important to look for providers with certified technicians and a proven history of successful rebuilds. Testimonials and case studies can give valuable insights into the provider’s capabilities and reliability. Additionally, a provider that offers a warranty on their work can give an extra layer of confidence in their services.

Technological Advancements in Spindle Rebuilding

The field of spindle rebuilding is continually evolving, with advancements in technology and techniques enhancing the effectiveness of the process. Innovations such as advanced diagnostic tools, precision machining equipment, and improved lubrication materials contribute to more efficient and effective spindle rebuilding. The integration of digital diagnostics tools, including advanced spindle testing devices, enables more precise identification of issues and targeted repairs. Automation in certain rebuilding processes ensures consistent quality and reduces turnaround times. Moreover, ongoing research in materials science leads to the development of more durable and efficient components, further enhancing the lifespan of rebuilt spindles.

The Role of Spindle Rebuilding in Sustainable Manufacturing

Spindle rebuilding is not only beneficial from a performance standpoint but also from an environmental perspective. By extending the life of existing spindles, rebuilding reduces waste and the need for new parts, contributing to more sustainable manufacturing practices. In an era where environmental impact is increasingly scrutinized, rebuilding and reusing components is a responsible choice. It aligns with the principles of circular economy, reducing the environmental footprint of manufacturing operations. Furthermore, by maximizing the use of existing resources, companies can exhibit their commitment to sustainable practices, which are increasingly valued by consumers and stakeholders alike.

Conclusion

The process of spindle rebuilding is a critical aspect of maintaining the precision and longevity of manufacturing equipment. By understanding the signs of spindle wear, engaging in regular maintenance, and selecting skilled service providers, manufacturers can ensure their machinery operates at peak performance for longer periods. The evolving technological landscape offers new opportunities to enhance the spindle rebuilding process, making it an indispensable practice in precision manufacturing. Spindle rebuilding represents a technical solution to a mechanical problem and reflects an organization’s commitment to quality, efficiency, and sustainability. As technology advances, the scope and effectiveness of spindle rebuilding will continue to grow, playing an integral role in the future of manufacturing.