Winter can be a challenging time for fleet truck owners and operators. The harsh weather conditions, icy roads, and freezing temperatures can significantly impact the performance and safety of your vehicles. To ensure smooth operations and minimize downtime, it’s crucial to properly prepare your fleet trucks for winter.

In this article, you will learn the essential steps to take in order to get your fleet trucks ready for the cold season.

1. Inspecting and Maintaining Tires for Winter Conditions

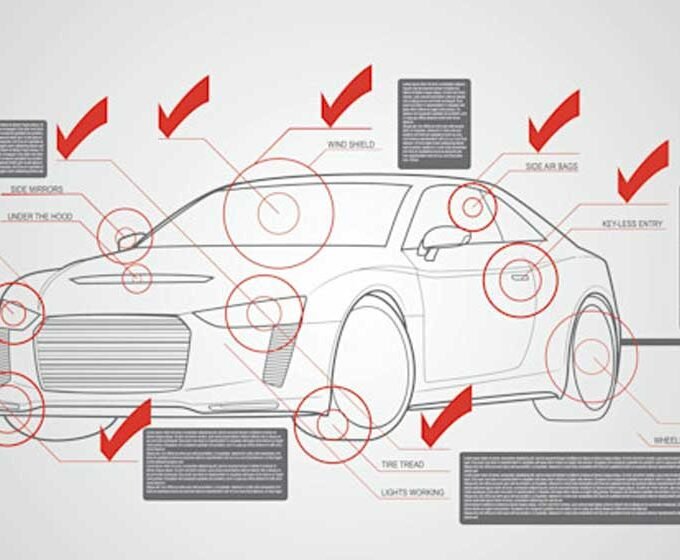

One of the most critical aspects of preparing your fleet trucks for winter is ensuring that the tires are in optimal condition. Start by inspecting the tread depth and overall tire condition. Worn-out tires can be extremely dangerous on slippery roads, compromising the traction and stability of your vehicles. Consider replacing tires that have reached the minimum tread depth recommendation.

Additionally, equipping your fleet trucks with winter tires can make a world of difference. Winter tires are specifically designed to provide better traction, handling, and braking performance in cold weather conditions. They are made of a different rubber compound that remains flexible even in freezing temperatures, allowing for improved grip on icy and snowy roads.

Finally, don’t forget to check tire pressure regularly throughout the winter season. Cold temperatures can cause a drop in tire pressure, which can affect fuel efficiency and handling. Keep a tire pressure gauge handy and ensure that all tires are properly inflated according to the manufacturer’s recommendations.

2. Getting Diesel Fuel Additives

Diesel fuel can be prone to gelling in extremely cold temperatures, leading to fuel filter clogs and engine performance issues. To prevent this, it’s essential to use diesel fuel additives specifically designed for winter conditions.

When selecting a diesel fuel additive, look for one that provides anti-gelling properties and improves the fuel’s cold-weather operability. Add the recommended amount of additive to your fleet trucks’ fuel tanks before the temperatures drop significantly. Regular use of these additives throughout the winter season will help to prevent fuel-related issues and keep your vehicles running smoothly. Just search “bulk diesel fuel additives” online to find a bulk supply of additives for your fleet trucks.

3. Ensuring Proper Visibility and Lighting

Good visibility is crucial for safe winter driving. Ensure that all exterior lights on your fleet trucks are functioning properly, including headlights, taillights, brake lights, turn signals, and hazard lights. Replace any burned-out bulbs and clean the lenses to maximize light output.

In addition to lights, make sure that the windshield wipers are in good condition. Worn-out wiper blades can hinder visibility by leaving streaks or smearing the windshield. Replace the blades if they show signs of wear or deterioration. Consider using winter-specific wiper blades that are designed to resist freezing and provide better clearing of snow and ice.

To improve visibility during snowfall or freezing rain, apply a hydrophobic windshield treatment. These treatments create a water-repellent coating on the glass, allowing for improved water runoff and increased visibility in inclement weather. Apply the treatment according to the manufacturer’s instructions before the onset of winter.

4. Equipping Fleet Trucks With Winter Emergency Kits

Winter weather can be unpredictable, and it’s essential to be prepared for any emergencies or unexpected situations. Equip each of your fleet trucks with a winter emergency kit to ensure the safety and well-being of your drivers.

The kit should include items such as these:

- Blankets or sleeping bags

- Non-perishable food and water

- Extra warm clothing and gloves

- Ice scraper and snow brush

- Shovel

- Road flares or reflective triangles

- Jumper cables

- First aid kit

- Flashlight and extra batteries

Ensure that your drivers are familiar with the contents of the emergency kit and know how to use them. Encourage them to regularly check and replenish the supplies throughout the winter season. A well-equipped emergency kit can make a significant difference in the event of an unexpected breakdown or weather-related incident.

5. Training Drivers for Winter Driving Conditions

Properly trained drivers are crucial for safe and efficient winter operations. Conduct winter driving training sessions for your fleet truck drivers to ensure that they are well-prepared for the challenges that come with winter conditions.

The training should cover topics such as these:

- Safe driving techniques on icy or snow-covered roads

- Maintaining proper following distance and speed in adverse conditions

- Recognizing and reacting to skidding or loss of control

- Pre-trip inspections for winter safety

- Emergency procedures in case of a breakdown or accident

Encourage your drivers to practice these techniques in a controlled environment before the onset of winter. Consider partnering with a professional driving school or a certified instructor to provide comprehensive winter driving training. Investing in driver training will help to reduce the risk of accidents, improve fuel efficiency, and protect your fleet trucks from unnecessary wear and tear.

6. Implementing a Winter Maintenance Schedule

Regular maintenance is essential for the overall health and performance of your fleet trucks, especially during the winter season. Develop a comprehensive winter maintenance schedule that includes routine inspections, fluid checks, and preventive maintenance tasks.

Here are some key maintenance tasks to include in the schedule:

- Regularly inspecting and cleaning the battery connections to prevent corrosion and ensure reliable starting power.

- Checking the functionality of the block heater and ensuring it is properly plugged in during extended periods of vehicle downtime.

- Inspecting and cleaning the air filters to prevent clogging due to snow or ice buildup.

- Lubricating door locks, hinges, and other moving parts to prevent freezing.

- Checking the condition and tension of the serpentine belt to prevent breakdowns in cold weather.

- Inspecting and testing the heater and defroster systems to ensure proper operation.

Adhere to the maintenance schedule strictly and keep detailed records of all inspections and repairs. Regular maintenance will help to identify and address potential issues before they become major problems, minimizing downtime and costly repairs.

7. Monitoring and Evaluating Fleet Truck Performance

Throughout the winter season, it’s important to monitor and evaluate the performance of your fleet trucks. Keep track of fuel efficiency, maintenance and repair costs, driver feedback, and any issues encountered during winter operations.

Regularly review fuel consumption data to identify any sudden changes or anomalies that may indicate a problem with a particular vehicle. Monitor maintenance and repair records to identify recurring issues that may be more prevalent during the winter season. Encourage your drivers to report any concerns or difficulties they experience while operating the fleet trucks in winter conditions.

Analyzing this data will help you identify areas for improvement and make informed decisions regarding fleet management and maintenance. It will also enable you to address any performance issues promptly, ensuring that your fleet trucks remain in optimal condition throughout the winter season.

Conclusion

Preparing your fleet trucks for winter operations is vital to ensure their performance, safety, and reliability. By following the steps outlined in this article, you can minimize downtime, reduce the risk of accidents, and maximize the efficiency of your fleet trucks during the cold season.

Don’t wait until winter arrives – start preparing your fleet trucks now to stay ahead of the game and maintain a competitive edge in your industry.