Metalworking equipment helps manufacturers create various products by shaping raw materials into finished goods. Automotive and household appliance manufacturers use this equipment to cut and shape metals. Here are some examples of the equipment used in manufacturing.

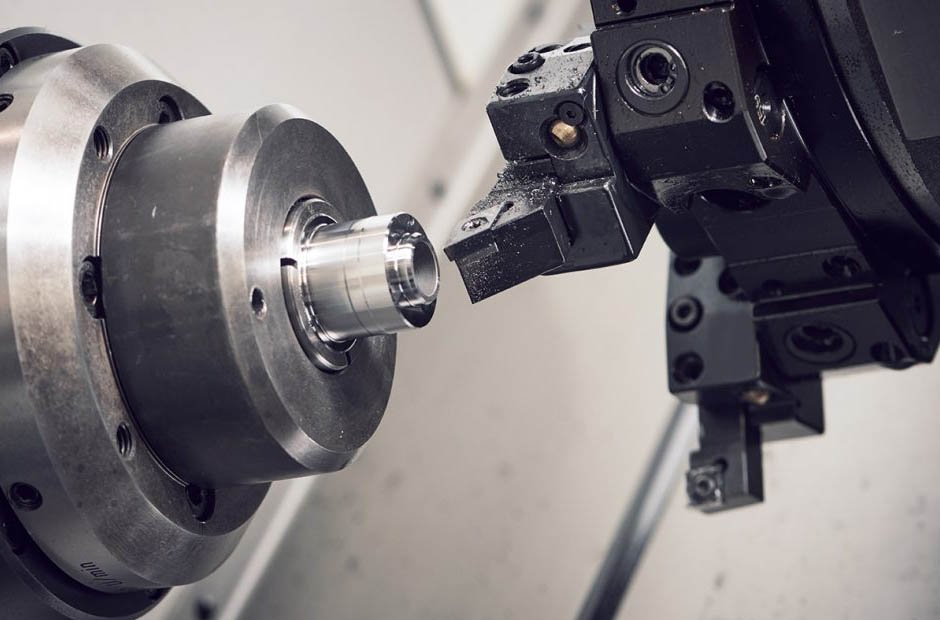

Lathe Machines

Lathes are an example of metalworking equipment that is used to shape cylindrical items. This equipment rotates the workpiece on its axis and cuts it to create a symmetrical object. These machines use processes like turning, facing, and tapering. They produce shafts, bushings, and pulleys through these processes. Lathe machines come in different configurations for small-scale and large-scale production facilities.

Milling Machines

Milling machines remove material from a workpiece using rotary cutters. They cut and shape components precisely for aerospace and electronics industries using vertical or horizontal mills for different needs. Milling machines are adaptable and allow manufacturers to create complex shapes. They also help engineers develop prototypes and produce various items in mass quantities.

Drilling Machines

Drilling machines bore holes into workpieces using rotating drill bits of various sizes. These machines are used in manufacturing to create holes in metal components. This is a common step in the assembly process. Drilling machines create reliable results and are used to produce metal components for several industries. They help to create parts for electronics, construction, and tools for other manufacturing processes.

Grinding Machine

Grinding machines are used for precision finishing and shaping processes. They remove excess material from a workpiece using an abrasive wheel. These machines help manufacturers achieve tight tolerances and smooth surfaces for products such as bearings and gears. Grinders create high-precision materials for various manufacturing sectors like aerospace, automotive, and tool production. Grinding machines are adaptable and efficient, which enables them to achieve high levels of accuracy and surface quality.

Welding Machinery

Welding equipment joins metal pieces by melting and fusing them using techniques like MIG, TIG, and arc welding. This manufacturing equipment helps create durable connections for large and small components. Automotive assembly lines and shipbuilding yards benefit from welding machines as they help strengthen the integrity of structures. Welding is a versatile manufacturing process that allows for the creation of joints that vary in strength and appearance. This makes it a good method for fabricating pipelines, bridges, and intricate metal sculptures. Welding machinery provides precision and reliability to professionals in the manufacturing industry.

Computer Numerical Control (CNC) Machines

CNC machines include mills and lathes, which are controlled by computer commands. These machines produce complex shapes and intricate designs with consistent output. CNC machines are used in the aerospace, automotive, and electronics industries. These machines use advanced technology to help them perform tasks quickly and precisely for maximum productivity.

Sheet Metal Equipment

Manufacturers use shears, punches, and press brakes to cut and form thin metal sheets. This equipment is used in manufacturing to produce components like panels, enclosures, and brackets. The automotive, HVAC, and electronics industries benefit from this type of equipment. Shears are used to cut large sheets of metal with straight and clean edges. Punches create holes and produce intricate patterns in sheet metal, offering various design options. Press brakes bend metal sheets to precise angles. This precision helps manufacturers form complex shapes using sheet metal. These tools are tailored for tasks in both small-scale and large-scale manufacturing facilities.

Waterjet and Laser Cutting Machines

Waterjet cutting machines use water subjected to high pressure and abrasive particles to cut through materials. Laser-cutting machines use focused laser beams to burn through metal. Both of these metalworking machines are highly efficient and precise. They allow manufacturers to perform intricate and detailed cutting tasks, which is valuable in the aerospace and custom metal fabrication industries. This equipment uses materials efficiently and helps to reduce waste products. This makes waterjet and laser cutting machines environmentally friendly metalworking tools.

Buy Metalworking Equipment From Trusted Dealers

The manufacturing industry relies on several types of metalworking equipment to transform raw materials into finished products. Some of the manufacturing processes that use metalworking tools include shaping, cutting, and joining metals. The equipment used in these processes must be precise, efficient, and safe for users, so purchase it through a trusted dealer. Contact a reputable machinery dealer today to find innovative and efficient equipment for your metalworking and manufacturing needs.