Explore the intriguing world of contemporary construction processes as we take a behind-the-scenes look at cutting-edge approaches influencing tomorrow’s structures. 3D printing is transforming architectural possibilities, and augmented reality is redefining project planning. The construction business is undergoing a spectacular change. Examine the special advantages that cutting-edge technologies like thin joint masonry raised access flooring and self-healing concrete are providing in terms of boosting sustainability, efficiency, and durability.

Building with Augmented Reality:

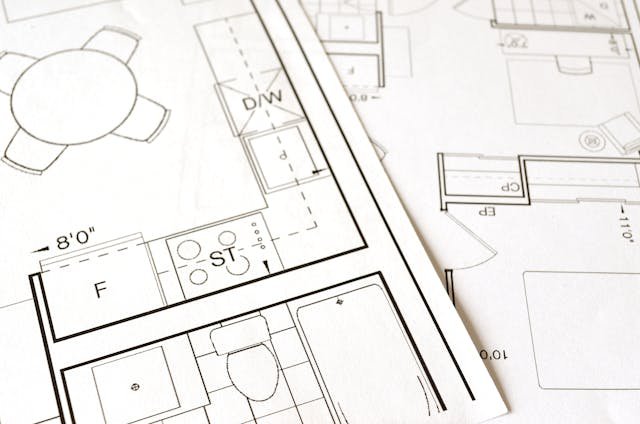

With the ability to overlay data in real-time and visualize it on physical buildings, augmented reality in construction is revolutionizing the planning and execution of projects. By using AR, contractors can increase team communication, streamline workflows, and identify conflicts, all of which contribute to quicker and more accurate construction processes. Stakeholders can use AR to see intricate designs in three dimensions, spot any problems before the building starts, and make well-informed decisions to reduce risks. Additionally, AR makes it easier to seamlessly integrate AR with technologies like BIM and AutoCAD drawing downloads, which support a comprehensive approach to construction management and increase cooperation and synergy among project stakeholders.

Elevated Access Floor:

In contemporary buildings, raised access flooring systems provide a versatile way to control utilities like data, HVAC, and electricity. By raising the floor level, these systems improve accessibility for repairs and maintenance by providing a place underneath for cables, pipes, and other infrastructure. Raised access flooring also creates an air void, which enhances air circulation and thermal efficiency and results in more comfortable interior spaces. Interior spaces may be quickly altered to match changes in technology and layout requirements without causing large disruptions because of the versatility of these technologies. Raised access flooring also enhances a building’s aesthetic appeal by offering a smooth, consistent surface that goes well with a variety of architectural designs.

Concrete That Heals Itself:

Concrete that can mend itself is a novel technology that increases a structure’s resilience by fixing cracks on its own. This novel substance effectively seals damage and stops further deterioration by releasing healing ingredients when cracks occur through embedded capsules or bacteria. Self-healing concrete helps buildings last longer, saves maintenance costs, and maintains structural integrity by proactively filling in small gaps. This technology is especially useful in places with high traffic or severe environments where concrete structures are prone to damage. Engineers and architects can create longer-lasting, more resilient structures with self-healing concrete, guaranteeing communities have safer and more sustainable infrastructure.

Slim Joint Masonry:

Thin joint masonry is a building method that produces long-lasting and visually beautiful walls by using thin mortar joints and exact alignment. Thin joint masonry increases structural stability while using less material by having mortar joints as thin as 3 mm. Because mortar sets more quickly with this procedure than with traditional brickwork, construction can be completed more quickly. Furthermore, thin joint masonry has better acoustic and thermal insulation qualities, which raises building occupant comfort and energy efficiency. Its exact alignment produces smooth, even joints that improve the built-in walls’ aesthetic attractiveness. Thin joint masonry delivers high-quality and reasonably priced construction solutions by combining efficiency and precision.

3D-Printed Structures:

Buildings made using 3D printing offer a revolutionary way to construct structures since they can be created layer by layer. With the unmatched creative flexibility provided by this cutting-edge technology, architects can now construct intricate shapes and geometries that would be difficult or impossible to do with more conventional techniques. 3D-printed buildings can be made more quickly and effectively with less material waste by using additive manufacturing techniques. Moreover, because it permits the use of environmentally friendly materials and lowers the carbon footprint connected with building operations, this strategy shows potential for improving sustainability in the construction industry. The goal of transforming architectural ideas into physical reality is getting closer to reality thanks to 3D printing, opening the door to a new era of inventive and efficient construction.

Conclusion:

Through the adoption of technologies such as thin joint masonry, raised access flooring, and self-healing concrete, the construction sector is ready to produce buildings that are not only long-lasting and effective but also sustainable and flexible enough to meet changing demands. Keep pushing the envelope of what is feasible since the construction industry’s future is expected to be characterized by innovation, productivity, and a dedication to creating a better world for future generations.